Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- CASE Ingredients Functions

- Plastics & Elastomers Functions

- EC No.

- 601-214-2

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Materials Features

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Plastics & Elastomers End Uses

- Plastics & Elastomers Processing Methods

- Applications

- Very well suited for Hydrophobic silica application.

- Well suited for Anti-settling application.

Typical Applications

- Plasticizers

- Blowing agents

- Antistatic agents

- Anti-fogging agents

Properties

- Physico-Chemical Properties

Value Units Test Method / Conditions Tamped Density (ex plant) approx. 60 g/l - Specific Surface Area (BET), Multipoint 230 - 290 m²/g - SiO₂ Content (based on ignited material) min. 99.8 wt % - pH Value (in 4% dispersion) 5.5 - 8.0 - Iso 787-9 Loss on Drying* (at 105 °C, 2 hours) max. 0.5 wt % ISO 787-2 Carbon Content 2.0 - 3.0 wt % -

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

- AEROSIL® Fumed Silica

- AEROSIL® fumed silica is a highly dispersed, amorphous, very pure silica manufactured by high-temperature hydrolysis of silicon tetrachloride in an oxyhydrogen gas flame. The primary particles formed in the AEROSIL® process are virtually spherical and free of pores.

- During the formation of the primary particles, aggregates are formed which further accumu- late into agglomerates. Under shear, these agglomerates can be returned back into smaller aggregates.

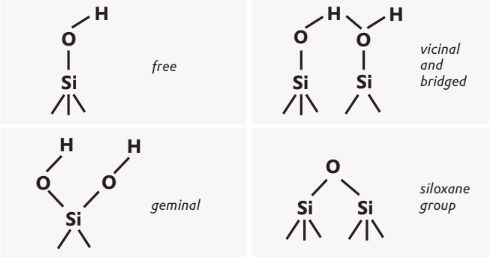

- Siloxane and silanol groups are found on the surface of the AEROSIL® particles. This latter type of functional group in particular is responsible for the hydrophilic behavior of untreated AEROSIL®. Figure shows the surface groups of hydrophilic AEROSIL® grades.

Surface groups of hydrophilic AEROSIL® grades.

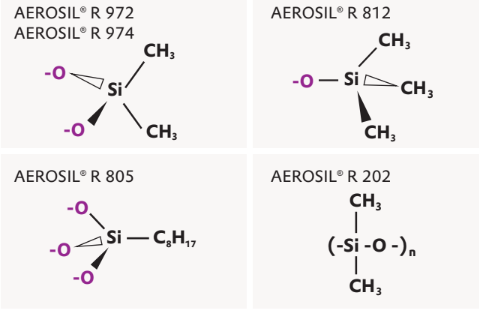

Figure below provides a summary of these and highlights the difference between them and hydrophilic AEROSIL® grades according to the schematically represented surface groups. All hydrophobic AEROSIL® grades bear the suffix “R” to indicate their water- repellent character.

Surface groups of hydrophobic AEROSIL® grades.

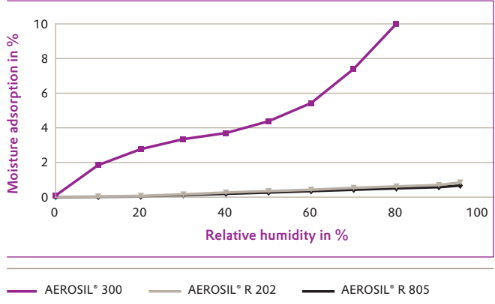

The hydrophobic nature of aftertreated AEROSIL® grades compared with AEROSIL® 300 can be illustrated by means of moisture adsorption in increasingly humid conditions. Figure below shows the corresponding isotherms.

Adsorption isotherms of various AEROSIL® grades at room temperature (small samples).